Water scarcity is a growing problem for regions around the world, with more than five billion people expected to experience “water stress” by 2030, according to the World Resources Institute. Desalination of sea and brackish water offers a potential solution to water scarcity, but conventional methods for removing sodium chloride from natural water resources are energy-intensive and therefore costly, hindering large-scale adoption.

Inspired by the deep expertise and innovative battery advances in the ME department, Assistant Professor David Kwabi is leading a research team that’s taking a new approach—an electrochemical approach—to desalination.

“When it comes to electrochemical devices to solve large-scale societal problems such as renewable energy storage to address climate change, we place a lot of emphasis on batteries. At its core, battery technology aims to move a charge efficiently from one electrode to another, and in fact several attributes of today’s Li-ion (lithium ion) batteries are also highly desirable for desalination applications,” Kwabi said.

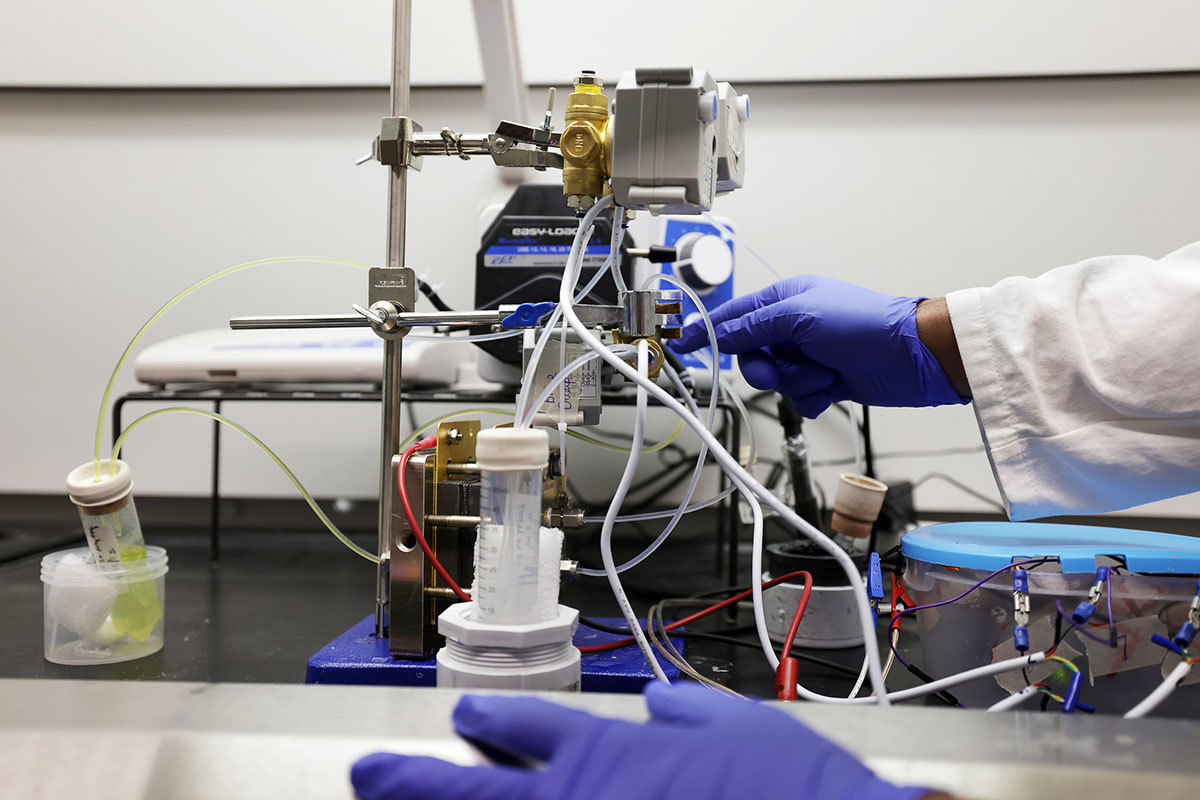

Siddhant Singh, mechanical engineering PhD student, demonstrates the work he's been doing with an electrochemical flow cell designed to desalinate water for David Kwabi, mechanical engineering assistant professor, at the Battery Lab.

Siddhant Singh, mechanical engineering PhD student, demonstrates the work he's been doing with an electrochemical flow cell designed to desalinate water for David Kwabi, mechanical engineering assistant professor, at the Battery Lab.

Kwabi and three ME colleagues are leveraging the synergies between energy storage and desalination applications with an ME Research Innovation Pilot grant, awarded for their work investigating “Energy-efficient water desalination using a hybrid electrochemical flow system.” The RIP grant program is intended to support multidisciplinary collaboration and catalyze new research directions. Along with Kwabi, who serves as lead principal investigator (PI), the team includes co-PIs Jeff Sakamoto, professor; Wei Lu, professor; and Don Siegel, formerly a professor in ME at U-M, now at University of Texas at Austin. The work spans computational science, materials design and synthesis, and battery construction, areas in which team members have made significant contributions.

Together, the group has been working to develop an energy-efficient electrochemical system to remove sodium chloride from brackish and sea water. Electrochemical desalination is a promising approach for several reasons. It can be powered by renewable electricity, used on a small-scale, distributed basis (such as by a small community with access to brackish water) and it’s more energy efficient than—and overcomes key challenges of—conventional desalination methods, including thermal desalination and reverse osmosis.

The proof-of-concept system the team has developed relies on a pair electrochemical reduction and oxidation, or “redox,” reactions, in a liquid electrolyte and a solid, chloride-reacting electrode. The electrolyte and electrode are separated by a single, ceramic membrane, unlike other desalination systems that require two or more membranes.

The ceramic membrane, pioneered by Sakamoto for use in Li-ion batteries, selectively moves sodium ions with near 100% efficiency. It is also impermeable to water, which all but eliminates the osmotic loss of water from the desalinated stream; every mole of charge results in salt uptake or release. “Most traditional polymer-based membranes fall short in this respect,” Kwabi said.

In the team’s design, salt-containing water is circulated between a reservoir and the solid electrode. Desalination occurs when a current is applied to the solid electrode, causing chloride ions to be intercalated, or trapped, within it, while sodium ions migrate through the ceramic membrane into the liquid electrolyte. When the current’s direction is reversed, the chloride and sodium ions move in the opposite directions, and the salt can be dumped into a separate “waste” reservoir.

The design is reminiscent of redox-flow batteries, an emerging technology for low-cost storage of grid electricity, and enables the electrolyte and electrode to regenerate and perform repeated and unlimited desalination cycles. Reversibility also helps recover some of the invested energy and further improve efficiency. The team initially set a performance target to produce potable water from synthetic seawater with less than 5 kilowatt-hours of energy per cubic meter of desalinated water.

Critical to the desalination process is the composition of the chloride-reacting electrode. Siegel, who performs computational screening of battery electrode compounds, is leading the design and atomistic simulations of potential materials to intercalate chloride in the desalination system.

Lu brings expertise in predictive continuum-level system models and is modeling how the new desalination system works so as to identify operational parameters that maximize energy efficiency.

With Kwabi’s expertise in flow batteries, he is quantifying the rate of salt uptake and release and the energy efficiency of desalination across various regimes of current density, initial salt concentration, and degree of salt removal.

In principle, the flow cell system can cycle multiple times to reach the desired salinity. Seawater typically contains about 0.6 moles (35 grams) of sodium chloride per liter of water. Approximately 99% must be removed for water to be drinkable. The waste sodium chloride could be used in other processes, including large-scale industrial processes to produce caustic soda, or lye.

To date the team has proved the concept with a cell that can desalinate up to about 5 grams of salt per liter of saltwater in a single cycle using a silver-based solid electrode. Next, the group plans to refine and improve individual components, for example reducing the thickness of the ceramic membrane to further improve energy efficiency.

Data the team is generating from this proof-of-concept phase will be used to expand efforts and establish a major research program focused on electrochemical water desalination.

“Countless research opportunities exist in environmental remediation, and our mechanical engineering community is clamoring to apply traditional ME disciplines to these new challenges,” Kwabi said. Although at first advanced battery design might seem like a very different engineering problem from seawater desalination for potable water, it’s hardly a stretch for Kwabi and the team. “There are so many synergies we can leverage.”