Physical Review Materials (PRMaterials), launched in 2017, is a broad-scope journal publishing high-quality research on materials. The journal serves the multidisciplinary community working on the prediction, synthesis, processing, structure, properties, and modeling of a wide range of materials.

Abstract: The superior strength-to-weight ratio endows aluminum (Al) alloys with great potential to be used in aerospace, automotive, and defense applications. The mechanical performance of Al alloys are largely dictated by the interactions between dislocations and precipitates introduced into the Al matrix, because precipitates could impede the dislocations’ glide motion in slip planes and thereby enhance the system’s strength. Specifically, in Al alloys with supersaturated solid solution of copper (Cu) atoms, Guinier-Preston (GP) zone is known as the very initial stage of the precipitation sequence and plays a critical role in determining the system’s overall age hardening behavior. Therefore, a piece of fundamental knowledge on the dislocation-GP zone interaction under various environments is of crucial importance to develop Al alloys with desired properties.

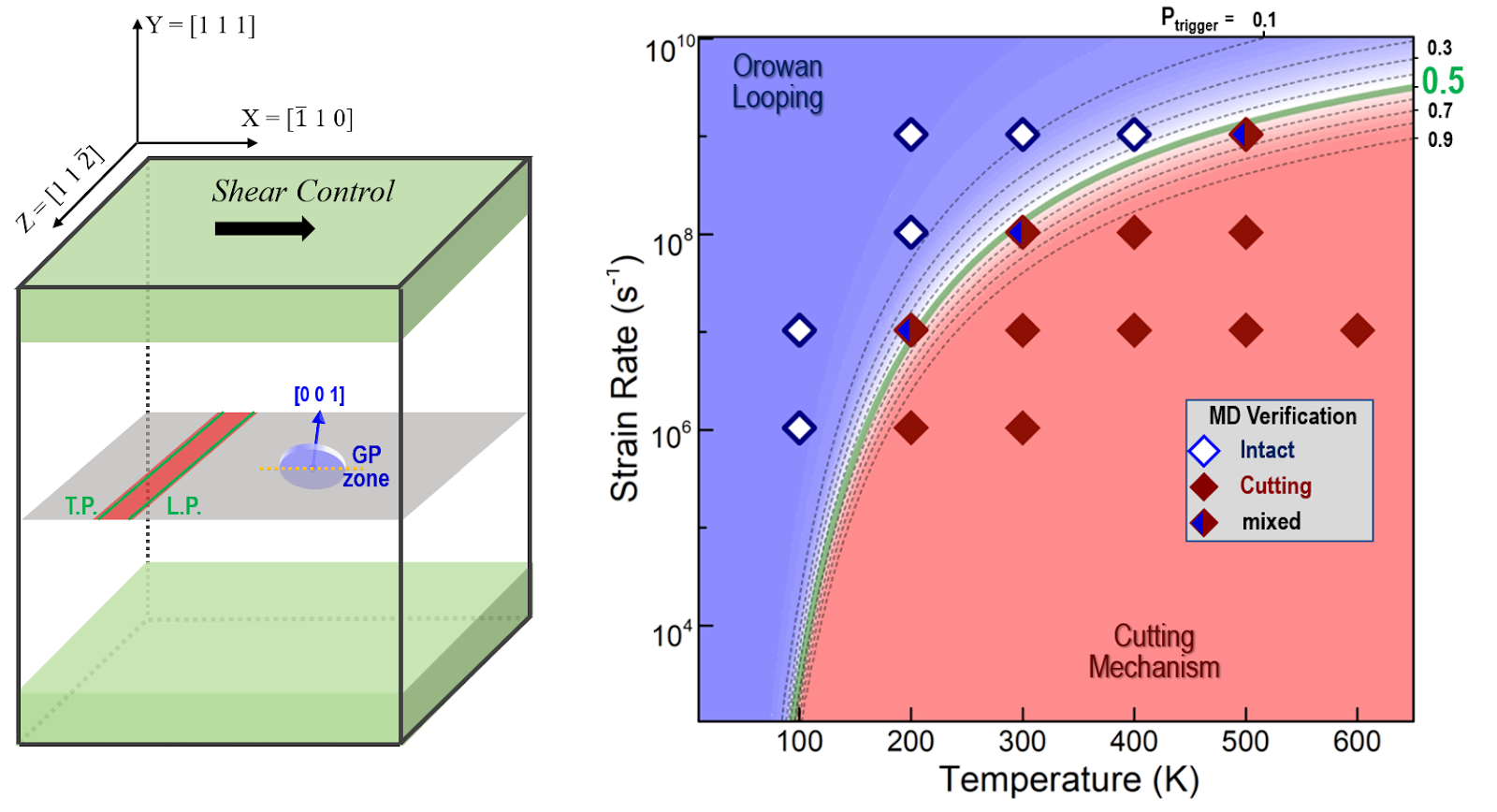

In this study, the interaction between a ½[](111) edge dislocation and a GP zone on the (0 0 1) plane under different thermo-mechanical conditions are examined by atomistic modeling. In contrast to the reported Orowan looping interaction, the GP zone is also observed to be cut by the glide dislocation. By quantifying the non-linear coupling effect between strain rate and temperature using transition state theory, the probability of occurrence of the cutting mechanism is predicted over a broad range of parameter space. It is demonstrated that, at experimental conditions, the cutting mechanism is overwhelmingly more probable than the Orowan looping mechanism. This leads to a reduction of GP zone’s growth rate, which provides a natural and viable explanation to the discrepancies between the existing model and experimental measurements. The so-constructed probability map, in conjunction with the established multi-scale modeling framework, might pave the way to a new and orthogonal route to improve the physical fidelity of predicting Al-alloys’ microstructural evolution and mechanical performance at prescribed conditions.

Read the full article here.