At low temperatures, along the hulls of cargo ships, the wings of airplanes, and the blades of wind turbines, gathering moisture develops into frost, adding excess weight that places significant strain on machines and can impair the performances of necessary mechanisms. Often, companies, workers, and consumers must give up their time, money, and/or labor, delaying and even shutting down operations, to address this potential safety hazard. “In Michigan in the winter we often wait for airplanes to be de-iced before takeoff,” said Yimin Zhou, Graduate Student Research Assistant in Mechanical Engineering. Yet, “to date there is no ideal material that can be applied as ice-repellent surfaces in industry.” Fortunately, innovative, new technologies are being developed to curb the effects of gathering moisture and frost.

Some engineers are working to design new oil-impregnated materials for building ships, airplanes, wind turbines, and other machinery, in an effort to reduce the amount of frost that develops over their surfaces. When moisture attempts to latch onto these materials, a layer of oil, embedded in a porous metal, acts as a barrier, repelling much of any developing frost and maintaining the integrity of mechanisms that might otherwise be damaged.

Regular, costly maintenance will still be required, however, to ensure efficacy and safety, as the oils used will eventually deplete. There is also, apparently, some debate about which oils are the most effective, which qualities should manufacturers prioritize in designing efficacious oil-impregnated materials. A student-led team in the Energy Transport Laboratory, in U-M Mechanical Engineering, recently investigated.

The project began when a team member noticed the striking formations that developed over a series of frozen water droplets. “We just saw these really interesting shapes in the beginning, and they hadn’t been recorded before, or they hadn’t been talked about,” said Hunter Gandee, an undergraduate in Mechanical Engineering and first author of the paper the team recently published on this research.

Oil-impregnated surfaces function by not allowing moisture to collect, forcing water droplets to slip off before latching and freezing. “One of the main reasons that these surfaces are being suggested for anti icing applications is because they have extremely low adhesion strength,” Hunter told us.

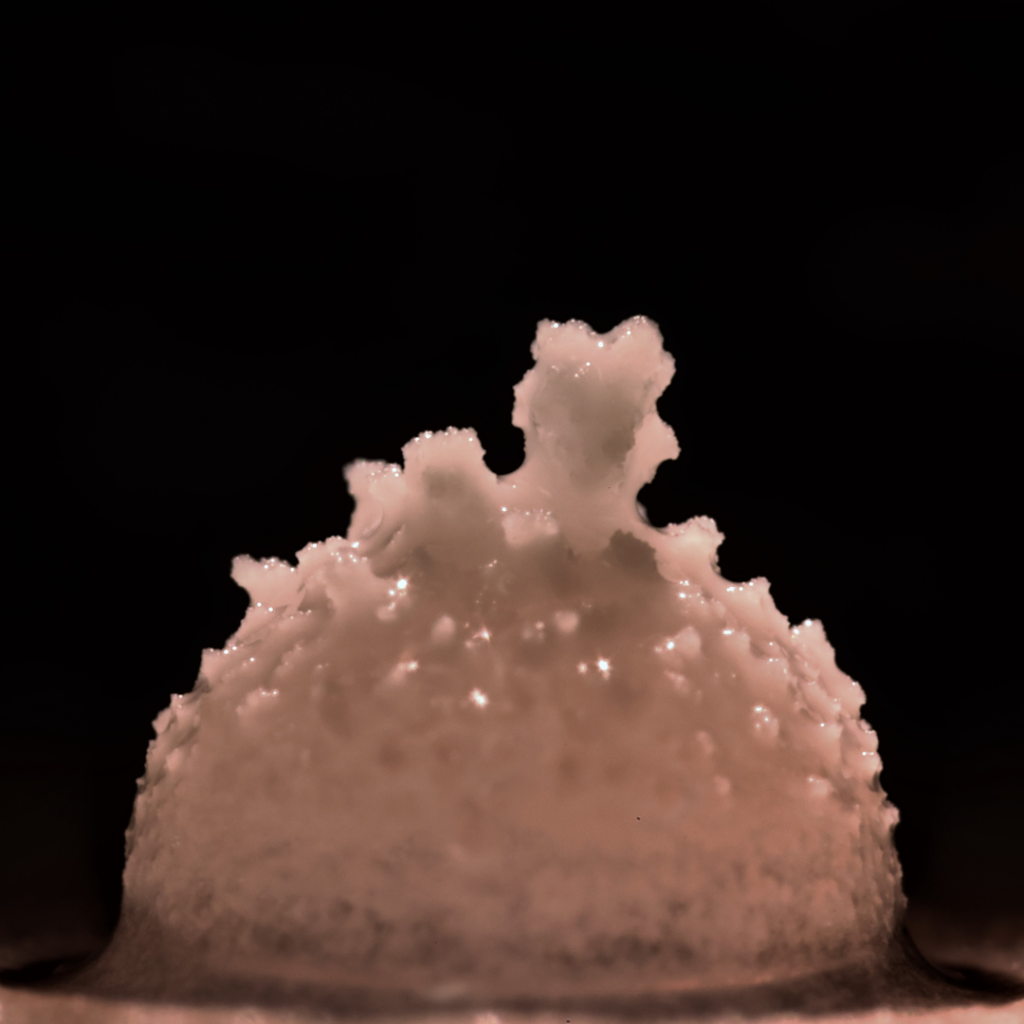

Stubborn droplets sometimes manage to hold on, though, freeze, and propagate what appear like miniature forests of ice, or tiny inverted snow globes. The question that compelled the team to study the picturesque formations was why they appeared to be growing differently on oil-impregnated surfaces than they were on other, more traditional surfaces designed to repel frost.

When a droplet freezes, the oil impregnated in the surface on which the droplet sits begins to wrap or cover the droplet. On traditional surfaces, the frost that grows from the frozen droplet will be sharp, pointy, and branching, but on these advanced materials, the “unique dendrite formations” are more thick and lumpy.

“Once the frost first starts to grow, there’s a network of these dendrites everywhere, and then the shape of these dendrites pulls the oil from the surface up and into the droplet to form this covering layer,” Hunter said. “Once you have a covered droplet that the dendrites are continuing to grow through, they’re then growing through a layer of oil, and that’s what’s causing this change in shape.”

Through careful analysis of this oil “wicking” and the development of these lumpy ice dendrite formations, the Energy Transport Laboratory team gained new insights into the effects of oil viscosity, oil chemistry, and other contributing factors on new oil-impregnated materials. The regime map they developed as a design guideline, they hope, will inform strategies to reduce oil depletion, a major bottleneck for the transition of oil-impregnated ice-repellent surfaces from laboratory prototypes to industry standards.

“The oil depletion process is complicated because oil exists in both the textured solid substrate beneath [the main oil layer] and the porous frost network on the frozen droplet,” said Yimin Zhou. “We hope that future study can have more quantitative experimental measurements and analytical modeling of the oil-ice-substrate interaction on oil-impregnated surfaces.”

The Energy Transport Laboratory’s principal investigator is Solomon Adera, Assistant Professor of Mechanical Engineering. Read more in the Energy Transport Laboratory’s paper, “Unique ice dendrite morphology on state-of-the-art oil-impregnated surfaces,” recently published in PNAS.