The American Society of Mechanical Engineers has selected ME Professor Jyoti Mazumder to receive the Thomas A. Edison Patent Award for the development of closed loop Direct Metal Deposition (DMD) technology.

The American Society of Mechanical Engineers has selected ME Professor Jyoti Mazumder to receive the Thomas A. Edison Patent Award for the development of closed loop Direct Metal Deposition (DMD) technology.

The award recognizes creativity of a patented device or process that has the potential to significantly enhance some aspect of the field of mechanical engineering. Mazumder’s DMD technology, which was patented in 2000 and has since acquired more than ten additional patents related to it, has certainly had a profound impact on the field thus far. Devices that operate on DMD technology are used not only in the United States but also in Europe, Asia and Australia.

When DMD was first conceptualized in the mid-1980s, it was intended as a process of rapid prototyping. Mazumder played a key role in developing the technology from a design aid that produced plastic parts into a method of creating functional metal components.

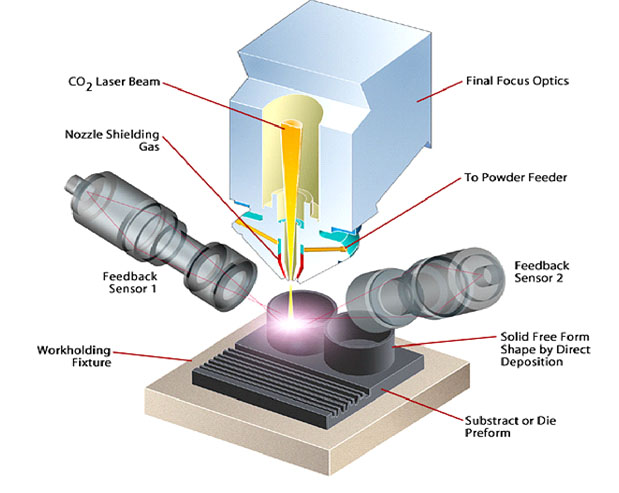

“[DMD] allows you to realize the part straight from the drawing,” explained Mazumder, describing a technique called Art to Part. Because of its ability to produce a part very near net shape directly from CAD, DMD can shorten lead time tremendously. Mazumder developed the technology to work on a closed loop system, a feature which keeps the outcome fixed while the input continuously varies. The closed loop system collects information from the light being produced by the laser and provides feedback to the laser and the CNC machine to modify the process as necessary.

DMD technology can be applied in nearly any field that requires the production of a three-dimensional component. “Your imagination is the limit,” said Mazumder of the possible uses for DMD. In healthcare, using the technology to create prostheses presents an especially promising application, as it allows custom-fitting components to be produced quickly and accurately. One of Mazumder’s current patents is for the development of Remote Controlled DMD to be used by the US Army. The device would make possible the production of a part in Iraq, for example, while direction of the process takes place in the US, saving a significant amount in transportation costs.

This diagram illustrates the closed loop feedback controller.

Mazumder’s work with DMD represents only one aspect of his research at the University. As director of the Center for Laser-Aided Intelligent Manufacturing (CLAIM), he and his research group study the plasma present in laser processing and attempt to understand the basic physics of the interaction between light photons and material electrons. A fundamental understanding of this process can be used for a variety of functions such as to control the deposition and to determine the composition of the microstructure being produced. “This light is illuminating,” he commented. Other current CLAIM projects include exploring surfaces that are most conducive to efficient fuel consumption and developing sensors to predict defects during production processes.

Mazumder prefers to focus both on obtaining patents for devices that the general public will benefit from and on conducting research whose most immediate impact is in academia, such as in physics journal publications. “I use my research to help day to day people,” he said. “At the same time I try to understand the physics so that a student ten years from now can learn it.” This dedication to the practical and theoretical motivations behind mechanical engineering research makes Mazumder a worthy recipient of the Edison Patent Award.