U-M News Center – One of the challenges for today’s 3-D printers lies in vibrations caused as they work. A printer’s movable parts, particularly in lightweight desktop models, cause vibrations that reduce the quality of the item being produced. And the faster the machine moves, the more vibrations are created.

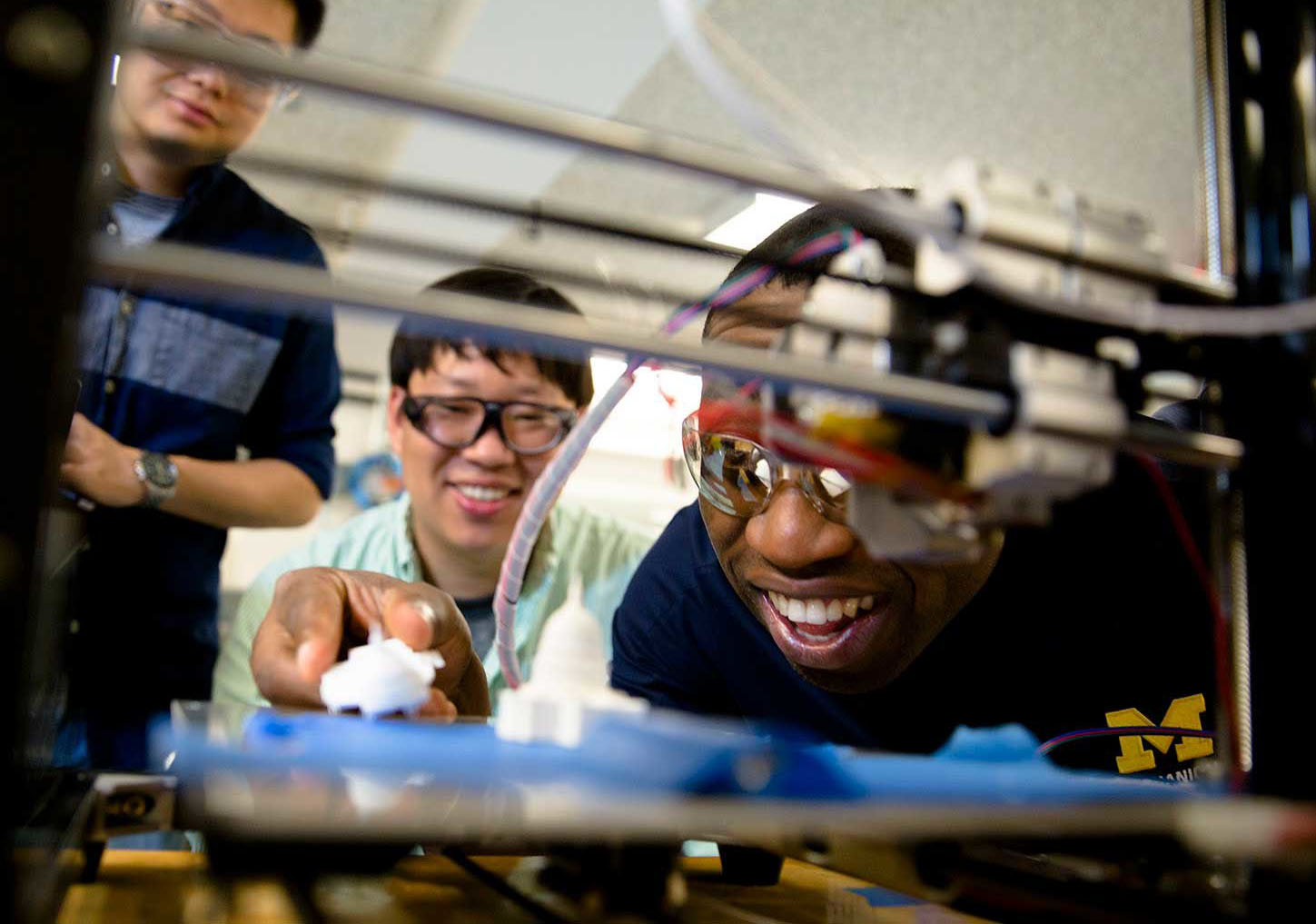

“Armed with knowledge of the printer’s dynamic behavior, the program anticipates when the printer may vibrate excessively and adjusts its motions accordingly,” said Chinedum Okwudire, an associate professor of mechanical engineering who directs U-M’s Smart and Sustainable Automation Research Lab.

To ensure details are reproduced accurately, the machines are operated slowly. And the pace of 3-D printing is one of the factors that has prevented the technology finding a broader audience.

Okwudire cited statements made last year by one 3-D printing company executive about the issues holding the industry back.

“We’re just waiting for the next evolution of the technology,” Simon Shen, CEO of XYZPrinting, told TechCrunch last year. “If they can do it much faster, more precise and easier, that will bring more people to 3-D printers. Not waiting for four to six hours for a print, but 40 to 60 minutes.”

Okwudire’s research was recently featured on Discovery Channel Canada as well as on several 3D printing news outlets around the world:

- U-M News Center – 3D-printing gets a turbo boost from U-M technology

- Additive Manufacturing – 3-D Printing Gets a Turbo Boost From U-M Technology

- 3ders – University of Michigan professor doubles 3D printing speeds using vibration-mitigating algorithm

- 3D Printing Industry – How to cut FFF 3D print times in half by the University of Michigan

- TechXplore – Software algorithm speeds 3-D printing