A framework bridging computational modeling and practical application helps rapidly screen materials for storing methane, improving practical use of the natural gas

A new approach harnesses machine learning to search for materials to store methane, helping accelerate the adoption of methane as a cleaner alternative fuel for vehicles. The University of Michigan-led study is published in Physical Review Materials.

Although methane boasts a higher energy density and a 25% lower carbon footprint compared to gasoline, it remains a gas at room temperature, making it difficult to store. Up to this point, methane has been stored in heavy, highly pressurized tanks or at cryogenic temperatures, preventing practical adoption as a fuel alternative.

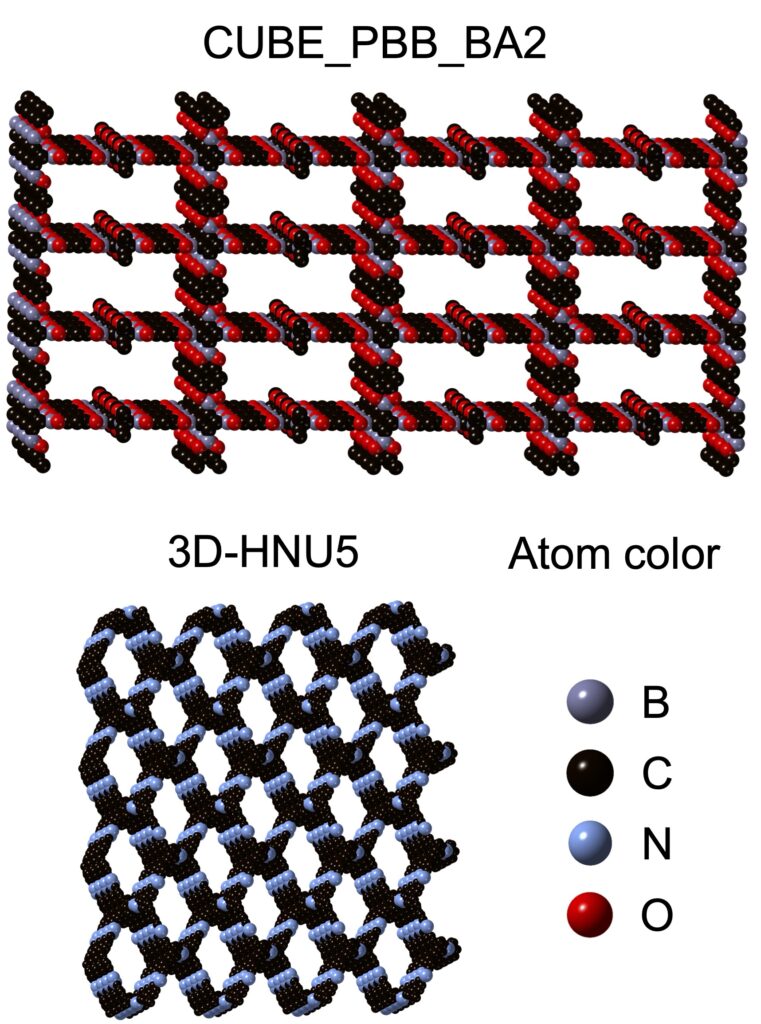

Recently, covalent organic frameworks (COFs)—a class of lightweight, highly porous materials—have been explored as an alternative storage method that works by adhering methane to their surfaces. While high-throughput computational screening has identified potential COFs, the sheer volume of possibilities and the need for extensive simulations limits progress.

“The pressing need for cleaner energy solutions motivates me to develop innovative, accessible, and efficient tools to optimize methane storage materials,” said Alauddin Ahmed, a U-M associate research scientist of mechanical engineering and corresponding author of the study.

The new approach combines machine learning with symbolic regression—a type of analysis that searches for the best mathematical equation to describe an observed dataset. The resulting, easily-interpretable equations predicted methane storage capacity with high accuracy at 4.2% mean absolute percentage error.

“By prioritizing physical, meaningful and measurable features, we’ve made it easier for experimentalists to apply these models directly, enabling broader participation in the field and accelerating the development of high-performance materials,” said Ahmed.

The high-fidelity models identified hundreds of COFs with superior performance, including some that meet U.S. Department of Energy targets for methane storage.

Bridging the gap between computational material discovery and practical application, the models empower researchers to rapidly identify promising methane storage materials without relying on expensive and time-intensive simulations.

This study assessed 84,800 potential COFs, marking the first application of symbolic regression to a large-scale dataset. A multistage computational workflow made this feat possible, reducing computational demands by identifying representative subsets of larger datasets (e.g., 400 COFs) for symbolic regression.

“We expected the symbolic regression models to struggle with the complexity of the dataset, given its size and the diverse nature of COFs. What surprised us was how effectively the multistage strategy worked, allowing the algorithm to derive interpretable equations that maintained high predictive accuracy even on unseen data,” said Ahmed.

The multistage approach also builds in flexibility, allowing equations to evolve as new data becomes available. The model’s adaptability offers a scalable framework for optimizing solid-state adsorbents like COFs or other areas like renewable energy storage, fuel cells and advanced batteries.

The combination of machine learning and symbolic regression could also be adapted to other domains such as catalysis, pharmaceuticals or any field involving a complex relationship between a material’s structure and its properties.

In a commitment to open science, all the datasets used in this research are publicly available on the Zenodo repository. The research used open-source software like RASPA and SISSO for simulations and symbolic regression.

This research was supported by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy (Grant No. DE-EE0008814). Additional computational resources and support were provided by the University of Michigan College of Engineering through subsidies for the ARC Great Lakes cluster.

Full citation: “Machine-learning-enhanced symbolic regression for methane storage prediction in covalent organic frameworks,” Alauddin Ahmed, Physical Review Materials (2024). DOI: 10.1103/PhysRevMaterials.8.115408